Materials

Materials

Production in zinc-aluminium alloys

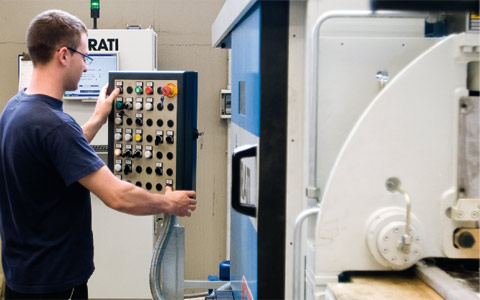

Then the mould holder is installed on the die-casting machine. Consequently the machine is set up by means of a software of the latest generation taking into account the dimensions as well as the die-casting technology to be used for the specific accessory. The zinc-aluminium alloy ingots are put into the burner, where the metal is melted at a temperature of 450° C.

The casting enters a siphon where a piston injects the material in an extension connected to the mould. After the die-casting the mould is cooled down and opened in order to extract the shot.

Once that the burrs and impurities have been detached, the accessory is handed on to the polishing and drying processes.

Production in polyester and natural materials

The working of raw disks, polyester bars and of disks in natural materials is done by means of the use of automatic machines obtaining finished buttons ready for polishing, trinkets and other accessories.

Thanks to the particular devices that can be applied on the machines, there can be carried out round, tilted, polygonal, irregular shapes etc. Furthermore the application of a laser unit on the machine allows to carry out any type of marking, incision, personalisation and shearing during the production of raw or finished buttons and accessories.